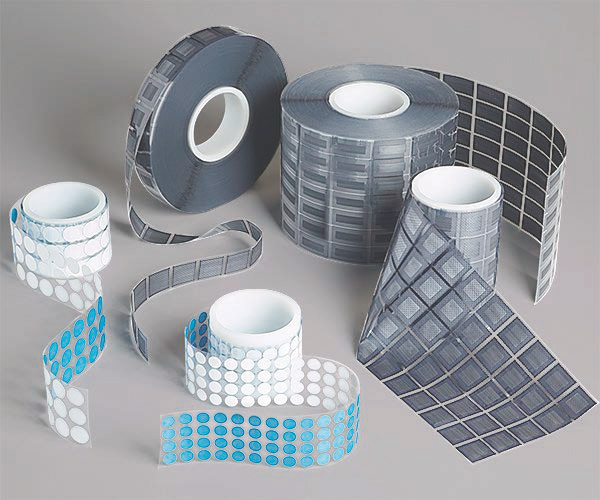

waterproof breathable membrane (also known as ePTFE membrane), is a new type of polymer waterproof material,Shangda SDA(e-PTFE) flm using expanded polytetrauoroethylene stretching uniform,to achieve three-dimensional network structure fiIm. Thediameter of the micropores is 0.1-10um, the molecules of air and water vapor are 0.0004um,and the pore diameter of the (Ce-PTFE)membrane is 250-25000 times larger than the diameter of the gas, so the gas Can pass through, while the diameter of capillary rain is500 pm, which is hundreds of times larger than the diameter of the micropores of the membrane.These micropores, which are only one twenty-thousandth the size of a drop of water, prevent water, dit and debris from entering (e-PTFE) the membrane. By allowing air to enter and exit the closed enclosure freely, equalizing pressure and preventing water,corrosive iquids,salts and particles from entering the enclosure and damaging the interior of the sealing equipment, our sealingequipment becomes more reliable, safer and more durable.

has been widely used in medical, precision electronics, LED outdoor lighting, automotive ights, communications, chemical, securilyand other industries. Today, we mainly introduce the three main production processes of waterproof breathable membrane.

1. Casting and compounding

this process is to use plastic particles hot melt after relying on the plastic itself adhesive compound. The disadvantage is that itisalmost airtight As of 2014,the world has not been able to use this process to produce real high-permeabilty, high-temperature

waterproof breathable film.

2, spray or scraping compound (hot melt adhesive compound)According to the coating online understanding, this process was first used in sanitary napkins and diapers, as well as protectiveclothing. At present, almost all domestic manufacturers use this process to produce highly breathable waterproof and breathablematerials. The disadvantage is that the air permeability is relatively low, because the pores of the intermediate breathable film are

actually blocked by hot melt adhesive

In addition, the most fatal disadvantage is that the temperature resistance is very low, can only withstand the temperature of 60degrees, Because this glue is actually a pressure-sensitive adhesive (Self-adhesive). A simple example is that in winter, double-sidedtape is almost non-sticky and delaminates. But in summer, the glue on the surface of the double-sided tape will melt, The quality ofthe waterproof and breathable membrane made by this process can be imagined.

3, hot pressing composite

the current domestic market is mixed, the production of real waterproof breathable film manufacturers are actually very few, manyfactories or sellers are promoting thelr own waterproof breathable flm is good, almost the vast majority of users have not thought of,some manufacturers provide waterproof breathable film is not waterproof.It is understood that the real waterproof breathable membrane should be high permeabilty, high temperature resistance, ant-aging.hyadrostatic pressure of more than 2 meters. The production process should be pure thermal composite technology, no glue, so it canreach a temperature of more than 110 degrees, high strength anti-aging, which is the current domestic products can really meet theEU standards, for the latest domestic technology.