the use of Shangda SDA cable waterproof connector, so thatlong-term exposure to outdoor products to obtain reliable waterproof sealing, effective solution to the large current,resistance heating, contact pressure and other factors. Inaddition, the normal electrical connection is ensured in case ofrainstorm, and the normal electrical connection is maintained inthe process of earthquake resistance during vibration, thuseffectively preventing the advantages such as flash break orpoor contact

| screw tooth specification |

Metric Tooth M |

|

| product material |

joint is adopted(brass nickel plated/stainless steel mesh/aluminum alloy), the clamping parts are made of nylon plastic (PA), and the seals and O-rings are made of nitrile rubber (NBR). |

| Product Certification |

European CE certification, European ROHS certification |

| protection level |

within the specified bayonet range, and use the O-ring seal to tighten the tightening head to IP68-10 bar pressure. |

| working temperature |

static:-40 ℃ to 100 ℃, short time up to 120 ℃. Dynamic:-20 ℃ to 80 ℃, short time up to 100 ℃ |

| thread length |

short threads are suitable for use in openings in thin plates or on equipment with internal threads, and long threads are suitable for engaging thick plates. Thread extension type can be customized. |

| Product Characteristics |

Clamping cable range, strong tensile strength, waterproof, dustproof, salt resistance, acid and alkali resistance, alcohol, grease and general solvents. |

| use method |

Metal cable waterproof connector is a supporting product of the cable. The connector can lock the cable, and the other end can be connected to the equipment box, or it can be connected to the electric equipment with internal threads at the inlet and outlet according to the selection of threads. |

| More choices |

can be customized according to the actual needs of customers. Need to order when welcome to inquire. |

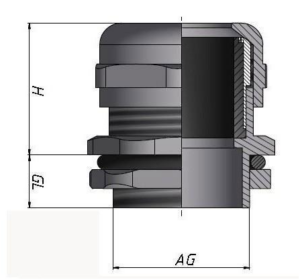

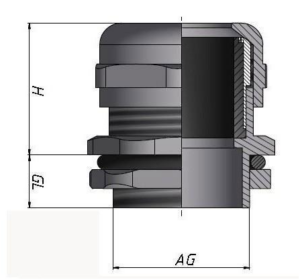

| metal cable waterproof joint—metric threadMSeries |

| Product Number |

thread specification AG |

Applicable cable (mm) |

thread outer diameter (mm) |

plate diameter (mm) |

thread length GL(mm) |

Joint length H(mm) |

Wrench Diameter (mm) |

| SD-M8 |

M8 * 1 |

5.5-2 |

8 |

8-8.2 |

5 |

16 |

12 |

| SD-M10 |

M10 * 1 |

6.5-3 |

10 |

10-10.2 |

7 |

19 |

14 |

| SD-M12 |

M12 * 1.5 |

6.5-3 |

12 |

12-12.2 |

7 |

19 |

14 |

| SD-M14 |

M14 * 1.5 |

8-4 |

14 |

14-14.2 |

7 |

19 |

17 |

| SD-M16 |

M16 * 1.5 |

8-4 |

16 |

16-16.2 |

8 |

20 |

18 |

| SD-M18 |

M18 * 1.5 |

10-5 |

18 |

18-18.2 |

8 |

21 |

20 |

| SD-M20 |

M20 * 1.5 |

12-6 |

20 |

20-20.2 |

8 |

22 |

22 |

Note: The above test data shall prevail in kind.