For chemical barrels and containers used in pesticides, consumer goods, industrial chemicals and other industries, the following problems are common before the use of protective products with good air permeability:

1. Chemical barrels and containers will experience changes in air pressure and temperature during transportation, resulting in changes in internal pressure, resulting in expansion and depression of the shell, which will not only affect the appearance, but also affect the reliability of its use.

2. Some chemicals are easily volatilized or decomposed to produce gas, which makes the pressure of chemical barrels and containers rise sharply, causing the shell to expand easily, and even cause the barrel cover or container wall to burst and cause serious leakage.

3. Some chemicals will react with the air to consume the air in the chemical barrel and container, thereby reducing the internal pressure and causing the collapse of the shell. In severe cases, it will tilt and cause leakage.

4. For chemical barrels and containers that use ordinary breathable products, there will generally be defects such as poor breathability and easy leakage. In the case of surfactants in the chemical, the breathable product also loses its breathability due to wetting by the surfactant.

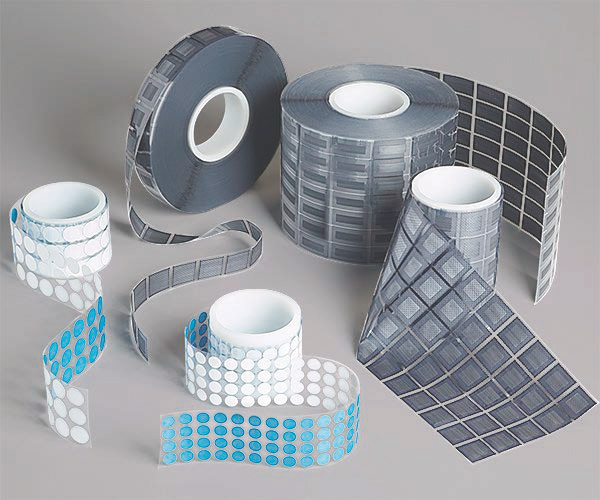

SDA’s waterproof and breathable protective products provide the best solution in chemical drums and containers in a variety of different industries. It ensures that the internal space communicates with the atmosphere in various situations while preventing liquid leakage in the chemical tank and container. At the same time, the waterproof breathable membrane has excellent chemical compatibility and can be suitable for the packaging of various corrosive chemicals. Products used in the packaging industry have adhesive waterproof breathable membrane , thread type waterproof ventilation valve.