General Guidelines

When installing adhesive-backed waterproof and breathable productson the shell, the following comprehensive factors are very important:1. The shell surface should be smooth; ensure that the shellinstallation surface is cleanclean, dry bath, surface contour withoutserrated or sharp edge;

2.Avoid direct sunlight, avoid close to heat sources, and avoiddust; the storage time does not exceed1 year.

3. The diaphragm installation position is arranged in the verticaldirection to avoid dust accumulation.

4. Apply obvious positioning line at the position where thediaphragm is installed, most of which is the limit step

5. Preparing blunt-edged tweezers Do not use tweezers that maydamage the waterproof, breathable product.

Operation Guide

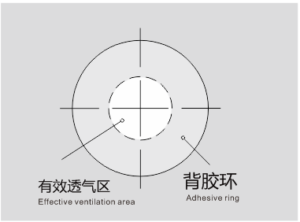

1). Operators should wear latex-free gloves or finger cots when operatingadhesive-backed breathable products;2). Avoid direct contact with the effective ventilation area of the product(Figure 1) or the adhesive ring;3). Keep all sharp or jagged objects away from the expandedpolytetrafluoroethylene (e-PTFE)breathable membrane;

Discovering Patch Guide

method1: Roll up the release material to separate the waterproof and breathablediaphragm from the release material, separate it to about 1-2mm, and then extract thediaphragm with a camera. See the following figure (1);(Fig.1)

method2: Place the product on a flat table top, gently pick up the diaphragm with a cameraand gently remove the diaphragm directly from the release material after 1-2mm is picked up;

Paste the diaphragm

1. Place the diaphragm accurately in the target limit interval. After placing and positioning thediaphragm, use your fingers to use abouta pressure of 30000 pa is applied vertically to thediaphragm for 5 to 10 seconds;(if there is a secondary mucosal film, the previous film shouldbe abolished, the paste interval should be cleaned first, and the new film should be pastedagain).

2. In order to ensure effective adhesion, rubber-assisted pressing tools should be used tomatch the ring-shaped adhesive. The rubber hardness is about30 degrees, the thickness can be2 to 5m,Compressing pressure approx.30000 pa,auxiliary pressing time approx.24 hours.

installation

1. Whether positioning is good

2, whether the waste material of the release material is attached to the diaphragm, if so, itshould be removed.

3, whether there is ash method, foreign matter, if there should be blown off