Plastic waterproof and breathable valve is a new type of waterproof and breathable component. Thewaterproof and breathable membrane is combined with plastic, silicone rubber and other materials throughembedded injection molding and hot melt welding to form a sealed installation component. Avoid dust, wateror other harmful substances while maintaining the balance of internal and external pressure of theequipment. It has the advantages of stable performance, simple installation, prolonged product life cycle,high waterproof and breathable performance

metal waterproof breathable valve is a new type of waterproof breathable component, the waterproofbreathable membrane through the form of riveting, combined with metal, silicone rubber and othermaterials, forming can be sealed installation parts; Can avoid dust, water or other harmful substances intowhile maintaining the internal and external pressure balance of equipment, with stable performance, simpleinstallation, prolong the product life cycle, waterproof breathable performance and other advantages.installation

1. Before installation, prepare a suitable sleeve or batch to adjust the torque2. Confirm whether the upper cover is properly covered and whether it will loosen. If it is loose, press ittightly to avoid falling

3. It is forbidden for personnel to uncover the upper cover and scratch the waterproof breathable membranewith their hands and fingers. Confirm the O-ring for damageInstallation Guide

1. Installation position

The position of the mounting hole is preferred to choose the side perpendicular to the ground, thewaterproof ventilation valve is installed horizontally, and the bottom installation is selected secondly, andthe position is not easy to be covered by rain, dust and other objects. In order to avoid being blocked by thecover waterproof breathable membrane micro-hole.

2. Design of mounting hole

When the wall thickness of the shell is less than or equal to 3MM, it is recommended to set the straight holetype and install it with the nut, when the wall thickness of the shell is greater than or equal to 3MM, it isrecommended to set the threaded hole type and install it tightly with the sealing ring:

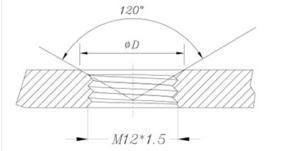

Snangda waterproof breathable valve M12*1.5 series products adopt O-ring with 14*g*2.5 and hardness of50, and have anti-O-ring overflow groove design.recommends a typical mounting hole chamfer of 120 degrees with a diameter of 14.2mm. The installationtorque of plastic waterproof ventilation valve is 6 to 7kgf.cm, and the installation torque of metal waterproof

ventilation valve is 13 to 15kgf.cm.Shangda company waterproof vent valve groove design is convenient for users to better carry out thechamfer design of threaded holes within the specified torque range:90 degree chamfer, from 12.0 to 14.6mm can be applied. 120 degree chamfer,from 12.0 to 15.omm can beapplied.